Desiccant Dehumidifiers

Desiccant Dehumidifiers — The Ultimate Humidity Solution

Our desiccant dehumidifiers are engineered to remove moisture in the vapour phase from air by using a high-performance desiccant rotor and adsorption mechanism. This allows you to achieve ultra-low humidity levels (even as low as ~1% RH) irrespective of ambient conditions, delivering dry, controlled air where conventional refrigerant-based dehumidification cannot.

Use & Importance

In critical industrial and commercial environments, even slight humidity variations can lead to condensation, corrosion, microbial growth, product spoilage, equipment failure or ice build-up. By leveraging desiccant dehumidification, you:

- Prevent condensation on surfaces, floors, ceilings and structural elements.

- Minimize lumping, caking and moisture-regain in powders and hygroscopic materials.

- Avoid frost or ice build-up in cold storage or low-temperature zones.

- Protect sensitive electronics, battery manufacturing, clean rooms and other precision processes from moisture-related risk.

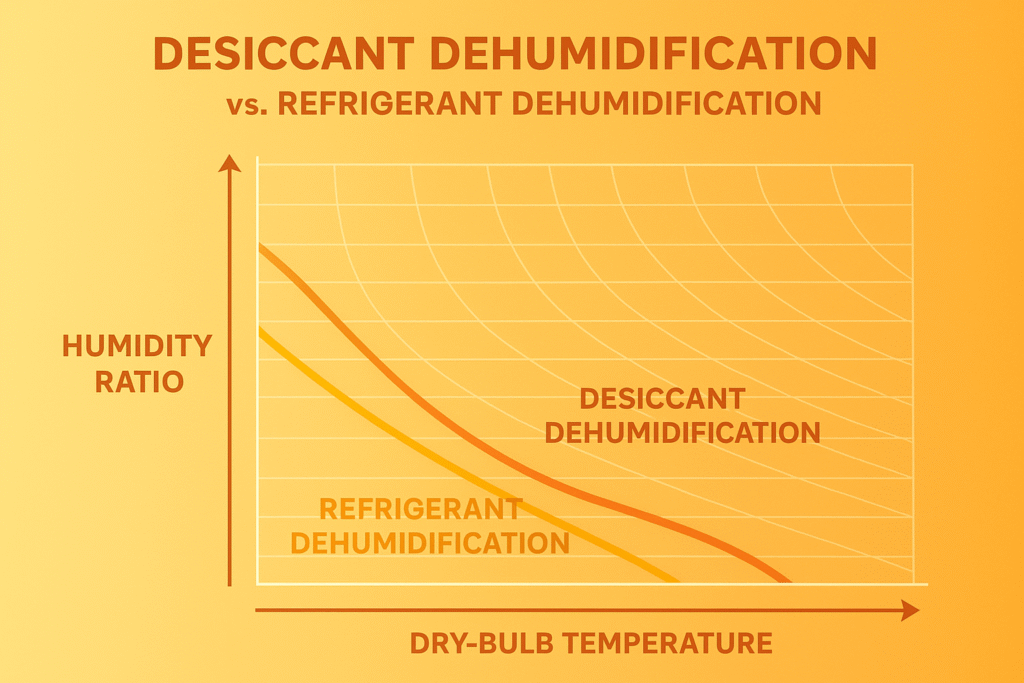

Why Desiccant Technology Leads in the Gulf Climate

In regions where humidity remains high even at lower temperatures, desiccant systems outperform refrigerant dehumidifiers. They deliver stable humidity control, reduce energy consumption, and maintain optimal air conditions for sensitive industrial processes — ensuring long-term reliability and compliance with environmental standards.

Applications

Our desiccant dehumidifiers serve a wide range of industry sectors, especially those in the GCC region facing high humidity:

Pharmaceuticals

Protecting tablet-coating, powder compression, sterile processing from moisture induced degradation.

Food Processing & Snacks/Candy/Chocolate

Preserving aroma, crispness, flavour, preventing sugar bloom, and spoilage.

Agriculture / Seed Drying & Storage

reducing microbial growth, preserving germination potential and shelf-life.

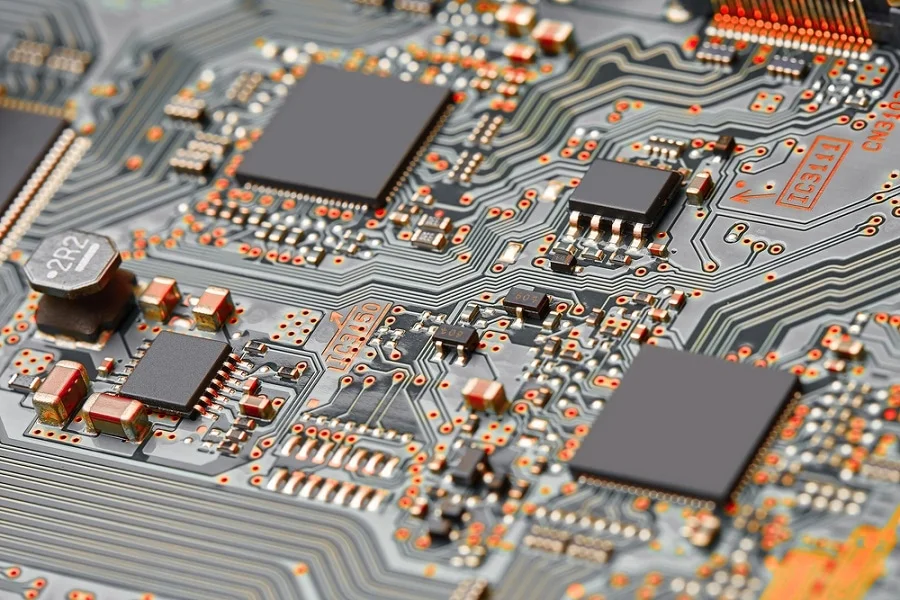

Electronics & Semiconductor

Maintains ultra-dry environments to prevent corrosion and condensation on sensitive components such as PCBs, sensors, and integrated circuits — ensuring higher reliability and longer product life.

Lithium Battery Manufacturing

Controls ambient moisture during cell assembly and module production, preventing moisture-induced reactions that can degrade performance or cause safety risks in lithium battery systems.

Hospitals & Healthcare

Ensures hygienic, moisture-free, and sterile air conditions essential for operating theatres, ICUs, and diagnostic rooms — protecting patients, equipment, and overall indoor air quality.

Clean Rooms

Maintains ultra-low humidity and contaminant-free environments crucial for research, testing, and precision manufacturing processes that demand strict air purity standards.

Cold Storage / Ice Rinks / Refrigeration Plants

Eliminates frost and ice accumulation on walls, floors, and cooling coils while improving refrigeration efficiency and reducing energy losses due to excess humidity.

Power Generation

Prevents moisture-related corrosion and insulation failures in turbines, generators, and switchgear systems operating in hot, humid environments — ensuring continuous and efficient power delivery.

Important Advantages

Precise Humidity Control: Maintain consistent ultra-low relative humidity levels even under extreme ambient conditions.

Energy Efficient Operation: Desiccant systems can outperform traditional systems when operating at low dew points or low temperatures.

Bacteriostatic: By removing the moisture that microorganisms need to grow, you reduce microbial and mould risk.

Low Maintenance & Reliable: Designed for long, continuous duty with minimal regeneration problems, no cycle changes across a wide humidity range.

Flexible & Customisable: Can be configured for indoor/outdoor installations, integrated with existing HVAC systems, mounted in tight footprints and engineered to your project’s specific airflow, capacity and environmental constraints.

Comprehensive Application Reach: Capable of operating at very low dew-points, reliable for industries demanding the highest air quality and dryness standards.